- Home

- Faq

- Circular Economy

- Embracing the Circular Economy: The Core Principles of TYC's Sustainable Approach

Embracing the Circular Economy: The Core Principles of TYC's Sustainable Approach

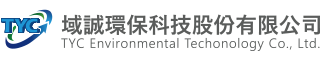

Explore the World of Circular Economy: How TYC’s 6R Model Revolutionizes Waste Management and Leads Businesses Toward a More Sustainable Future

As resources become increasingly scarce and environmental protection gains attention, the limitations of the linear economic model (take, make, dispose) are becoming more evident. This traditional model relies heavily on resource extraction and consumption, eventually leading to resource depletion and environmental degradation. In response to these challenges, the 3R model (Reduce, Recycle, Reuse) emerged, focusing on managing post-use waste, aiming to reduce waste and extend resource usage. However, the 3R model primarily addresses waste management and fails to fully meet modern businesses' higher sustainability demands, especially in supply chain management and resource regeneration.

TYC's 6R Circular Economy Model:

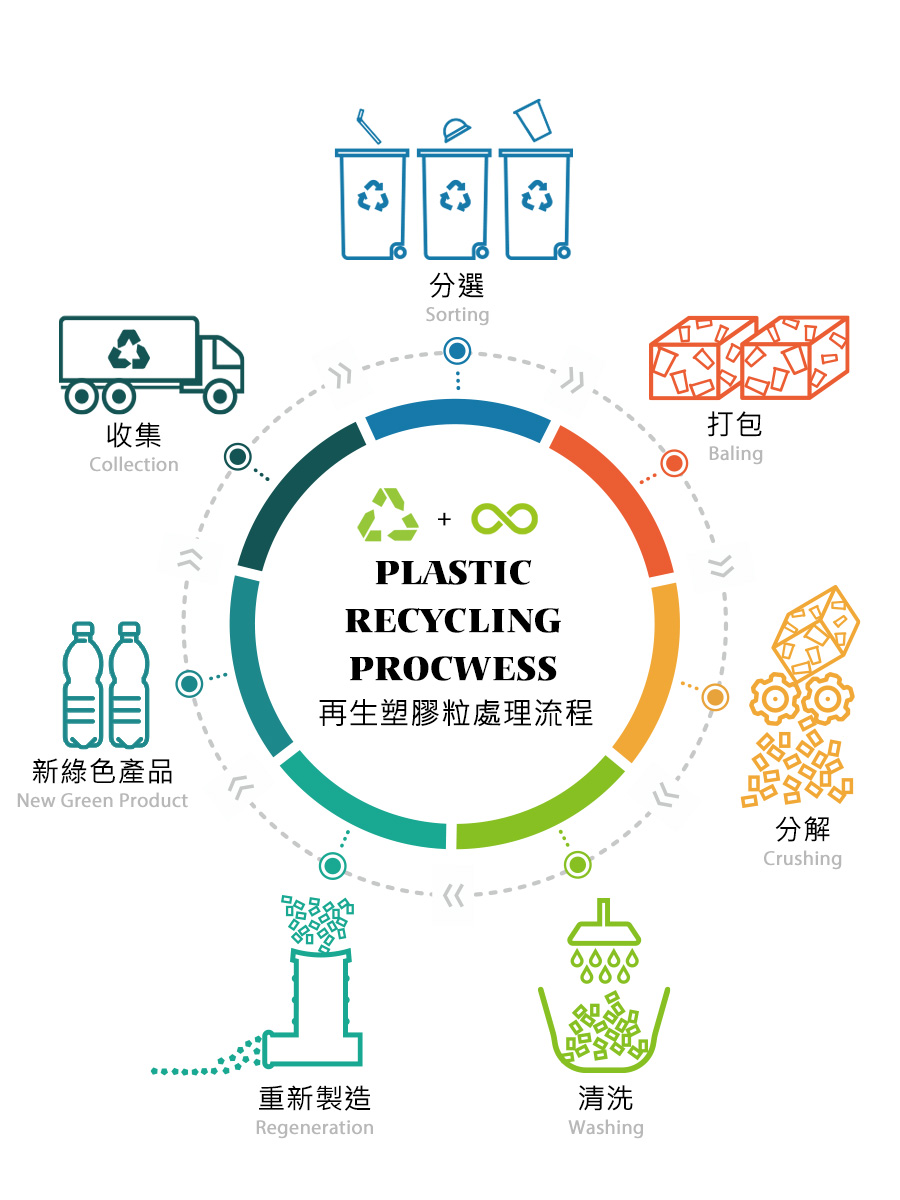

To address the shortcomings of the traditional 3R model, TYC introduced the 6R model, a more comprehensive approach to resource recycling. This model not only retains the principles of "Reduce, Recycle, Reuse" but also incorporates ReClean, Remanufacture, and Repurpose, reintegrating waste into the production chain to maximize resource utilization and transform waste management.

How the 6R Model Helps Companies Achieve Carbon Reduction Goals:

-

Reduce Raw Material Usage (Reduce): By reducing dependence on virgin materials, businesses can significantly lower carbon emissions, especially in the extraction, processing, and transportation of raw materials. This reduction in natural resource demand lowers the carbon footprint, helping businesses achieve carbon reduction from the source.

-

Increase Recycling Rate (Recycle): Using high-quality recycled materials to replace virgin materials saves substantial energy and significantly reduces carbon emissions associated with new material production. Compared to producing virgin materials, recycled materials can reduce carbon emissions by up to 80%.

-

ReClean: Through the ReClean process, recycled materials are ensured to meet the highest quality standards, enabling longer use of the materials and reducing the energy required for reprocessing, further lowering carbon emissions.

-

Extend Product Life (Reuse): Extending the lifecycle of products reduces the demand for single-use products, thus lowering the carbon emissions generated from repeated production. Reuse significantly reduces the carbon footprint associated with manufacturing and processing new products.

-

Remanufacture: TYC's remanufacturing process involves developing a materials database and incorporating AI technology to assist in developing new materials. This allows businesses to convert recycled materials into new products, reducing the demand for virgin materials and significantly lowering emissions during production.

-

Repurpose: Recycled materials can be used for new applications, creating more business value while reducing resource consumption and further lowering the carbon footprint. Repurposing innovation helps shrink carbon emissions across the supply chain.

Addressing the Shortcomings of the Traditional 3R Model:

-

Limitations of the Linear Economy: The linear economy depends on excessive resource extraction and consumption, leading to resource depletion and environmental pollution. The 3R model mainly addresses waste management but focuses on the post-use phase, neglecting resource optimization during the design and production stages, lacking a comprehensive strategy for material regeneration and product remanufacturing.

-

6R Model Solution: TYC’s 6R model expands the 3R framework, focusing not only on waste management but also on the production and design stages. Through material innovation, ReClean, and Remanufacture, it optimizes the entire lifecycle of resources. This not only increases recycling rates but also provides businesses with more innovative options and greater carbon reduction benefits.

Benefits of TYC's 6R Model:

-

Environmental Sustainability: The 6R model significantly reduces resource consumption and waste generation through comprehensive resource management and reuse strategies, effectively lowering carbon emissions. It also helps businesses achieve Scope 3 carbon reduction targets.

-

Economic Advantages: The 6R model enables businesses to create added value through remanufacturing and repurposing, reducing resource costs and giving companies a competitive edge in the market while achieving economic benefits from reduced carbon emissions.

-

Social Impact: The 6R model promotes material innovation and sustainable design, raising awareness of resource conservation and creating more employment opportunities, adding social value to the circular economy.

How TYC’s 6R Model Transforms the Industry:

TYC's 6R model not only addresses the limitations of the traditional 3R model in waste management but also overcomes the flaws of the linear economy. Through innovative technology and multi-level resource regeneration strategies, it maximizes resource utilization and leads businesses and industries toward sustainable development. As global companies increasingly prioritize environmental responsibility, TYC's 6R model sets a new standard for achieving green transformation, delivering significant carbon reduction benefits that help businesses move toward stainability goals.