- Home

- Faq

- Carbon Management

- Why Carbon Is Becoming a Measure of Business Efficiency? Step 1: Measurement

Why Carbon Is Becoming a Measure of Business Efficiency? Step 1: Measurement

Why Carbon Is Becoming a Measure of Business Efficiency

Step 1: Measurement

Carbon was once seen as a topic reserved for sustainability teams or large corporations.

That perception is changing.

Today, carbon is increasingly becoming part of how business efficiency is evaluated.

Carbon is no longer just an environmental metric.

It reflects how well a company manages cost control, resource efficiency, supply-chain stability, and operational predictability.

When carbon structure is unclear, businesses are not just exposed to emissions —

they experience efficiency loss, hidden costs, and weaker decision quality.

When carbon is measured and understood,

it becomes a tool to improve processes, strengthen operational performance, and support better management decisions.

That is why many companies are realizing:

carbon management is fundamentally an efficiency capability, not an additional burden.

The First Step Is Not Reduction — It’s Measurement

Before any improvement can take place, businesses must answer a basic question:

Where does carbon actually sit in our operations?

The purpose of measurement is not perfect data.

It is to establish a baseline that supports decision-making.

With measurement, companies gain visibility into:

-

Which activities consume the most resources

-

Which cost structures are most sensitive to change

-

Where operational efficiency can be improved

Without structure, improvement is guesswork.

With measurement, optimization becomes manageable, repeatable, and strategic.

Carbon Management Is Like Corporate Health Management

Companies monitor health not to assign judgment,

but to understand structure, identify inefficiencies,

and maintain long-term stability and performance.

Carbon measurement serves the same purpose.

It helps organizations understand:

-

Whether carbon is driven by energy, materials, or logistics

-

Which areas have the greatest impact on cost and efficiency

-

Where structural optimization is possible

You can’t optimize what you don’t understand.

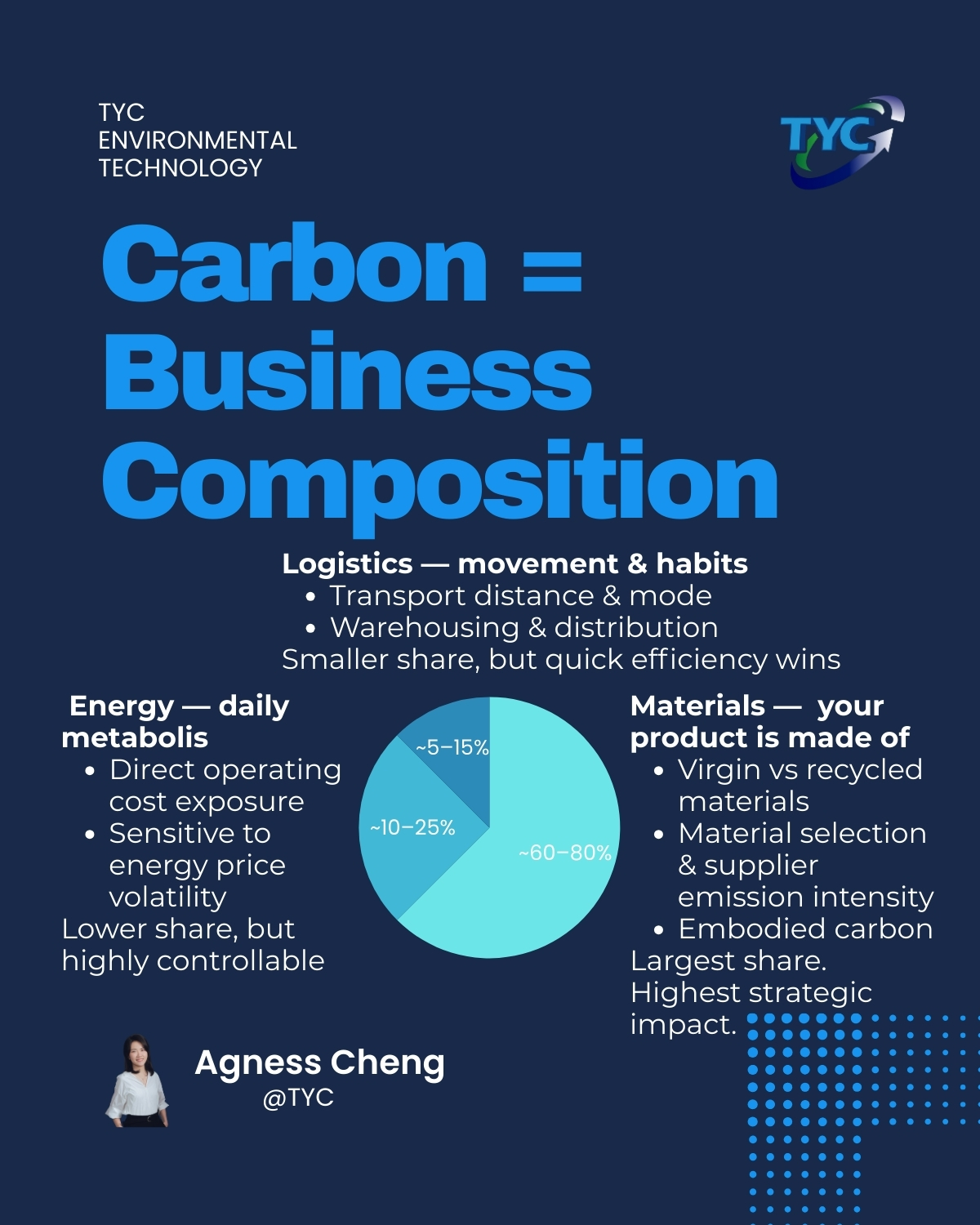

Why Composition Matters More Than Total Emissions

In practice, companies with similar total emissions

often have very different efficiency profiles.

The difference lies in carbon composition.

-

Manufacturing companies with material-heavy carbon profiles

face efficiency challenges related to sourcing, supplier structure, and material selection -

Service companies with energy-heavy profiles

are more sensitive to operational cost stability and daily efficiency management

This is why understanding where carbon sits

is more valuable than knowing how much carbon is emitted.

Measurement Is Not Reporting — It’s an Efficiency Lens

Carbon measurement is not about adding complexity.

It is about reducing uncertainty.

With structural visibility:

-

Cost volatility becomes predictable

-

Resource allocation improves

-

Decision-making quality increases

Transparency does not reduce efficiency.

It enables it.

Measure First: Know What You’re Made Of

Carbon won’t change what you sell.

But understanding your carbon structure will directly influence

your cost efficiency, operational stability, and long-term competitiveness.

If you want to turn carbon measurement into a practical tool

for improving business efficiency and decision quality,

we’re happy to help you start with measurement.