Why Plastic Film Recycling Is Becoming a Business-Critical Material Issue

♻️ Why Plastic Film Recycling Is Becoming a Business-Critical Material Issue

Among all plastic packaging materials, plastic films—including packaging film, stretch film, and protective film—account for more than 40% of total plastic packaging use, yet they also represent the lowest recycling rate across plastic categories.

This challenge is not driven by a lack of recycling intent.

Rather, it reflects the inherent characteristics of plastic films: lightweight structure, high contamination risk, and significant material variability.

Without professional and systematic processing mechanisms, most plastic films are ultimately downcycled or diverted to incineration, failing to re-enter the value chain.

📊 The Material Stage Is the Primary Source of Carbon Emissions

In corporate decarbonization strategies, energy use and operational efficiency are often addressed first.

However, in practice:

Approximately 60–80% of plastic product carbon emissions occur during the material production stage, not during the use phase.

This means that material selection often has a greater impact on overall carbon footprint than product lifespan.

For high-frequency, widely used materials such as plastic films, even small unit weights can translate into substantial emissions as impacts compound across supply chains—making plastic films a material contributor to Scope 3 emissions.

📊 Recycled Materials Offer Scalable Carbon-Reduction Potential

Compared to virgin plastics, recycled plastics can reduce carbon emissions by approximately 30–70%, depending on polymer type and processing pathway.

When plastic films are effectively recycled and converted into stable, application-ready materials, their value extends beyond waste reduction. They directly improve a company’s material structure and carbon profile.

For businesses, this represents a quantifiable, scalable, and operationally relevant decarbonization lever.

♻️ Recycling Is Not the End—Material Destination Defines Circularity

In reality, even when plastic films enter recycling systems, unstable quality or lack of downstream applications often prevents them from returning to products and value chains.

True circularity does not depend on whether materials are collected, but on whether three conditions are met:

-

Effective front-end sorting and contamination control

-

Stable regeneration into usable materials

-

Verified reintegration into products and industrial applications

Without the final step, circularity cannot be achieved.

🌱 Why Expertise Matters — TYC’s Material Management Perspective

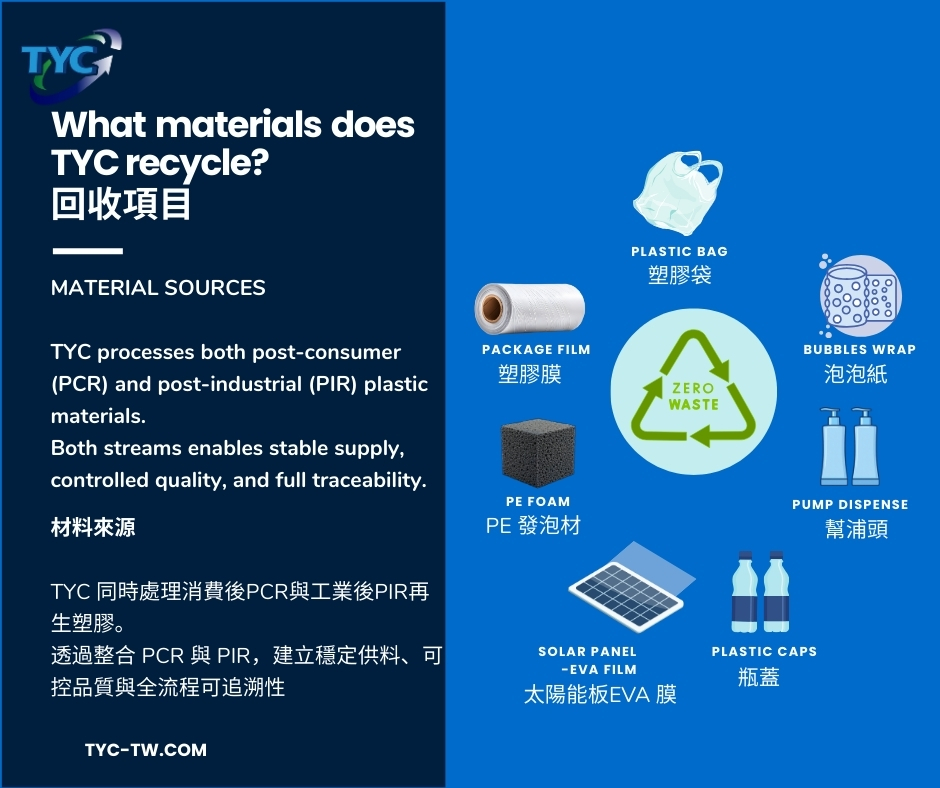

At TYC Environmental Technology, plastic film is not viewed as a waste problem, but as a material challenge that requires scientific and systematic management.

TYC treats plastic film as a material system defined by:

-

Structured identification and sorting

-

Stable and controlled regeneration processes

-

Quantifiable material and carbon data

-

End-to-end traceability across the value chain

-

Validation and quality control supported by a dedicated R&D team and in-house laboratory

Through this framework, recycling becomes more than an action—it becomes a measurable, manageable, and decision-relevant material solution.

♻️ TYC|Plastic Film Recycling Beyond Waste Management

As regulations, supply-chain expectations, and carbon disclosure requirements continue to tighten, plastic films—long overlooked—are rapidly emerging as a strategic material and risk-management issue for businesses.

Only materials that can be recycled, reused, and quantitatively managed will remain viable in future industrial systems.

From waste to material.

From recycling to real circularity.

📌 Learn more about TYC’s circular material solutions and data insights:

🔗 https://www.tyc-tw.com/faq/index/2